MIL-DTL-5421D

4.5 Individual tests. Each tube submitted for acceptance under contract shall be subject to the

following tests. In addition, each tube shall be subject to any additional test specified herein which the

inspector considers necessary to determine conformance with the requirements of this specification.

4.5.1 Examination of product. Each tube shall be examined to determine conformance

with the requirements of this specification not covered by applicable tests.

4.5.2 Leakage. The impact pressure opening and drain holes shall be sealed and a test

manometer connected to the impact connection. A pressure of 14.73 pounds per square inch (psi)

(30 inches of mercury) shall be applied. The pressure shall not drop below 14.71 psi (29.95 inches

of mercury) after a one-minute period.

4.5.3 Electrical circuit. The rated voltage shall be applied across the terminals of the tube

for a period of two minutes at an ambient temperature of 20 °C to 30 °C (68 °F to 86 °F). After the

two-minute period the power shall be 80 watts (W) +20/-5 percent.

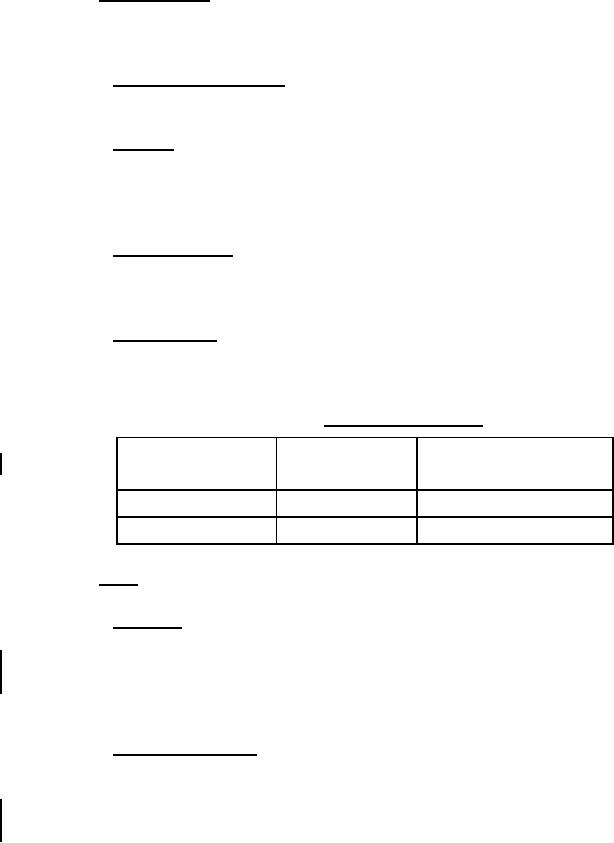

4.5.4 High potential. The tube shall be subjected to a high potential test with the voltages

listed in table I at a commercial frequency applied between each terminal and the case for a period

of 60 seconds. No damage to the wiring or insulation shall result from this test.

TABLE I. Potential test voltages.

Sea level

50,000 feet (altitude)

Tube type

1

550 VRMS

110 VRMS

2

1,250 VRMS

500 VRMS

4.6 Tests.

4.6.1 Vibration. The tubes shall be subjected to vibration such that a point on the tip of

the tube will oscillate 1/4 inch. The test shall be conducted for a period of three hours consisting

of one-hour periods at 1,000, 2,000, and 3,000 cycles per minute (Hz). Type I tubes shall be

operated at 30 VDC and type 2 tubes shall be operated at 120 VAC, 400 Hz, single phase

continuously during this test. No leaks or failures of any kind shall result from this test.

4.6.2 Power consumption. Each tube shall be supported vertically and fully immersed in

a water-ice mixture at a temperature of approximately 0 °C (32 °F) within 1/4 inch of the

mounting surface. The tube shall remain in this water-ice mixture for ten minutes. The electrical

connector pins shall then be connected through a test circuit containing a 7-ampere fuse for type

1 tubes or a 2-ampere fuse for type 2 tubes to a source of the applicable rated voltage. The initial

current surge shall not cause the fuse to fail. After the specified potential has been applied for a

period of five minutes, the power shall be measured and shall be 120 W +25/-0 percent.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business