MIL-PRF-38135C(USAF)

3.5.8 Static pressure. The pointer shall not change position due to internal leakage more than

1 knot when a pressure sufficient to cause full-scale deflection is applied.

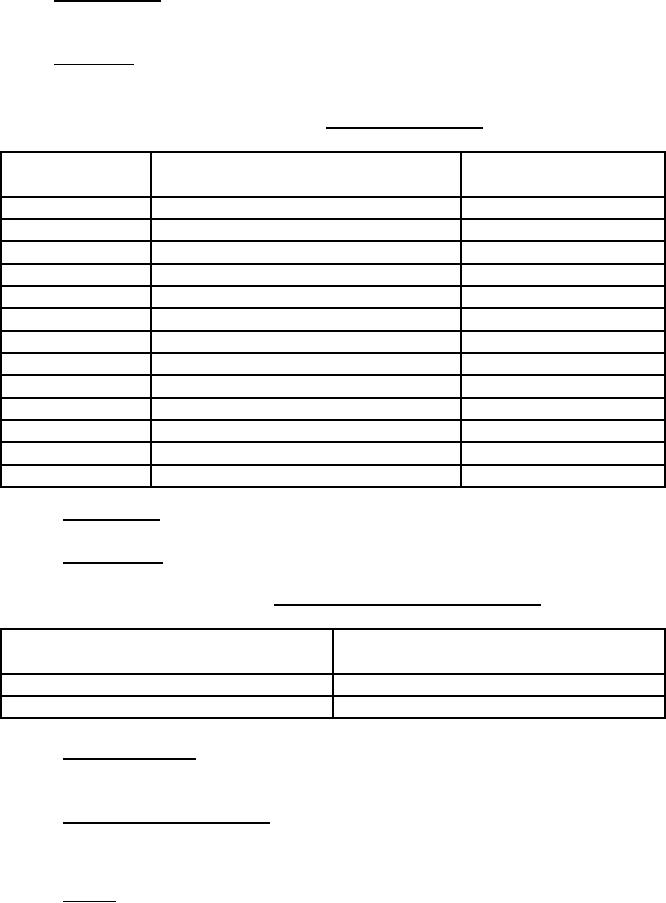

3.5.9 Scale error. The scale error (see 6.3.1) of the indicator shall be within the tolerances

specified in table II.

TABLE II. Scale error tolerances

Test point

Differential pressure

Tolerance

(±knots)

(inches Hg)

0

0

10

60

0.172

3

80

0.308

3

100

0.482

3

120

0.696

3

150

1.092

3

200

1.962

5

300

4.541

10

400

8.397

15

500

13.797

20

600

21.109

20

700

30.816

20

800

43.009

20

3.5.10 Friction error. The friction error shall be within the tolerances in table II.

3.5.11 Position error. The position error shall be within the tolerances in table III.

TABLE III. Friction and position error tolerances

Indicated airspeed

Tolerance

(±knots)

(knots)

60 to 200

3

201 to 850

10

3.5.12 Dielectric strength. The indicator shall withstand application of 500Vac between the pins

and case for 5 seconds without insulation breakdown.

3.5.13 Dial and cover glass location. The distance between the front surface of the bezel and the

outside of the cover glass shall be 0.062 inch or less. The distance between the inside surface of

the cover glass and the dial shall 0.125 inch or less.

3.5.14 Pointer. There shall be no oscillation in excess of ±5 knots of the pointer while the

indicator is vibrated. The pointer shall be adjustable. The pointer shall conform to MS33585-8

and shall be finished in lusterless white, color number 37875 of FED-STD-595.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business